More than 60% of companies that pursue continuous improvement do so to go from good to great (McKinsey). All companies possess unrealized potential, unseen opportunities that can make a difference for the bottom line and future of the company. When looking for ways to leverage this approach (or accelerate your current continuous improvement journey), it’s helpful to keep in mind some essential concepts and select your continuous improvement tools accordingly.

As such, we explain the steps to take when making changes to your current process in this article. The end objective? Make your improvement strategy more efficient, effective and scalable. Keep that in mind.

Continuous improvement techniques: PDCA, Kanban, Kaizen and more

Before we dive into useful tools to support your continuous improvement strategy, let’s revisit the common frameworks that have been developed over the past decades. Today, organizations use many of them to identify improvement opportunities.

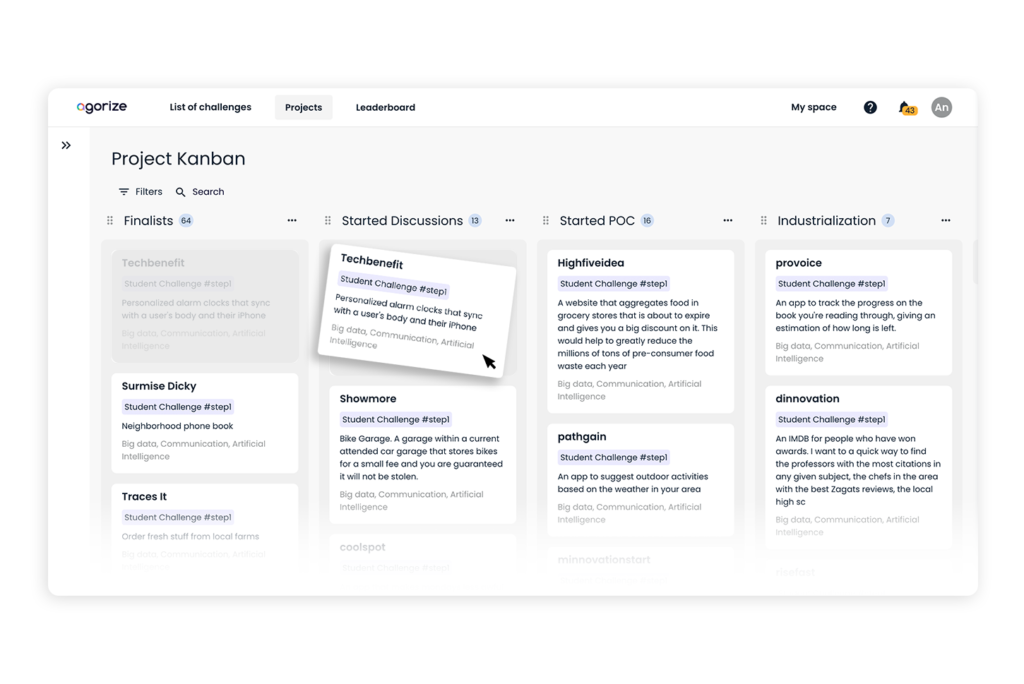

Kanban

First of all, we have Kanban. This is a visual method to illustrate, measure and highlight focus areas to enable continuous improvement. Nowadays, Kanban is a very commonly used technique as many teams follow a certain roadmap (Kanban boards) marked by task statuses to efficiently reach a goal. Ideas for improvement and improvement activities won’t lead to positive change unless (digital) tools like Kanban are help to align the stakeholders of the improvement program. Take a look at how its integrated in Agorize’s idea management solution.

Kaizen Continuous Improvement

Continuous improvement used to be called Kaizen. Originally, it is a Japanese philosophy built around the importance of flexible and open processes and systems. It helps organizations improve by constantly identifying and addressing issues. Moreover, by consistently improving even the smallest problems, organizations create a culture that encourages employees to adopt a continuous improvement mindset. And the method’s steps are as follows:

- Involve employees

- Find problems

- Create a solutions

- Test the solutions

- Analyze the results and determine whether to scale

- Repeat

Plan-Do-Check-Act (PDCA)

This method is an adaptation of Kaizen. The original goal was to manage quality control and the reasoning behind the technique is straightforward. The PDCA cycle, consists of Plan, Do, Check, Act.

Six Sigma

Lastly, the Six Sigma techniques helps limit errors in order to improve an organization’s capabilities. Six Sigma often uses PDCA for implementation and is based on five principles:

- Firstly, work for the customer

- Then, Identify root problems using data

- Stay proactive

- Use training and communication to keep team members involved

- And finally, be responsive and flexible

Some other techniques and frameworks include gemba walks, fishbone diagrams, 5 whys, value stream mapping (vsm) and root cause analysis. Read more about different techniques of lean management and incremental improvement and how to succeed in continuous improvement in a dedicated article here.

Bridging the gap between a process improvement framework and ROI

The continuous improvement methods mentioned above have had tremendous impact on every organization that wants to transform today. They have changed enterprise’s understanding and appreciation of the improvement and innovation process.

However, today, most leaders deal with workforces that are often global and diverse, largely digital and rapidly evolving. To leverage continuous improvement methods such that it creates value calls for tools or solutions. Such tools must facilitate and even accelerate the improvement process end-to-end, in a scalable manner.

5 essentials of digital continuous improvement tools

While continuous improvement often talks about processes and steps to take, it starts and ends with people. Thus, the frameworks should streamline their behavior and actions. Yet, the people within the organization are the ones that observe customer pain points, analyze data, and stay proactive and responsive. It’s why many leaders opt for an approach that focuses on creating a culture of continuous improvement, with dedicated operations within that culture to strengthen and leverage it.

Based on this notion, continuous improvement is about people, the solution you adopt must cover 5 essential domains to increase your chances of success.

1. Engagement

You must be able to engage large groups of people to create a culture of continuous improvement, a shared sense of responsibility, and an environment where everyone has a voice. Therefore, your ability to communicate to the relevant people at a large scale is key. A platform with global communication features allows you to spread the right messages at the right time.

Then, once they’re on board, people must be kept engaged throughout the improvement process and even beyond. Certain tools can help achieve this. Look for platforms with features that help recognize and reward good behavior, like a leaderboard of best participants.

2. Collaboration

When one employee identifies a detrimental bottleneck in your supply chain, it doesn’t mean they have the solution to that problem. That might be someone from an entirely different team or department. That’s where collaborative features of idea management platforms come in. When the tool you use offers features to share likes, comments, or extensive feedback, you’ll not only get to the root of your company’s problems, but you’ll collectively find solutions as well.

Throughout the entire process, you will have to work together with different departments and teams. In the first phases, you need input on problem statements. During assessment and mentoring rounds, you’ll call for dedicated experts from product, IT, legal or project management teams. In the end phase, C-level management will be asked to share their feedback on shortlisted ideas. A solution must have collaborative features for your digital improvement project.

3. Integration

The digital continuous improvement tool you opt for should smoothly integrate with or be able to integrate other tools in your stack. It can result in higher adoption rates of both admins and employees when the user experience isn’t disrupted. Looks out for things like single-sign on and full API-stack integration options.

4. Data-based decision-making

Remember when we said to keep in mind your end objective of continuous improvement? You want your continuous improvement efforts to be more efficient, effective and scalable. This can only be done with a clear understanding of measurable outcomes of those efforts. Data-based decision-making requires a continuous improvement solution that provides data about the ideas, people and outcomes linked to each project or program.

5. Scalability

The names says it all, continuous improvement is not a one-time event. Neither is creating a culture around that mindset. It’s a continuous effort that calls for repetition and high-adoption rates. Checking what the scalability of your potential tool is will help you in this regards. Some questions to validate this:

- Is there a limit on how many admins or participants can be onboarded?

- Will there be an issue translating your platform to launch it in different regions?

- Can you centralize all ideas from previous initiatives or programs in one place?

- Is there a feature, like Kanban, to visualize the idea funnel and get the most value out of it?

Thus, finding an effective way to gather ideas and improvement suggestions is how new value is created. These 5 selection criteria aim to improve your ability to select a solution that fits your needs.

Improvement tools you need to reduce go-to-market time by 60%

At Agorize, we help enterprise companies like PepsiCo, Majorel and Bayer reveal and assess talent and ideas that will support their transformation journey. For example, our IDEA BOX is idea management software that helps you gather these ideas from your ecosystems in one place. As a result, our clients have reduced go-to-market time from 24 to 9 months, improved processing time by 50% and achieved 3x faster skills transfer.

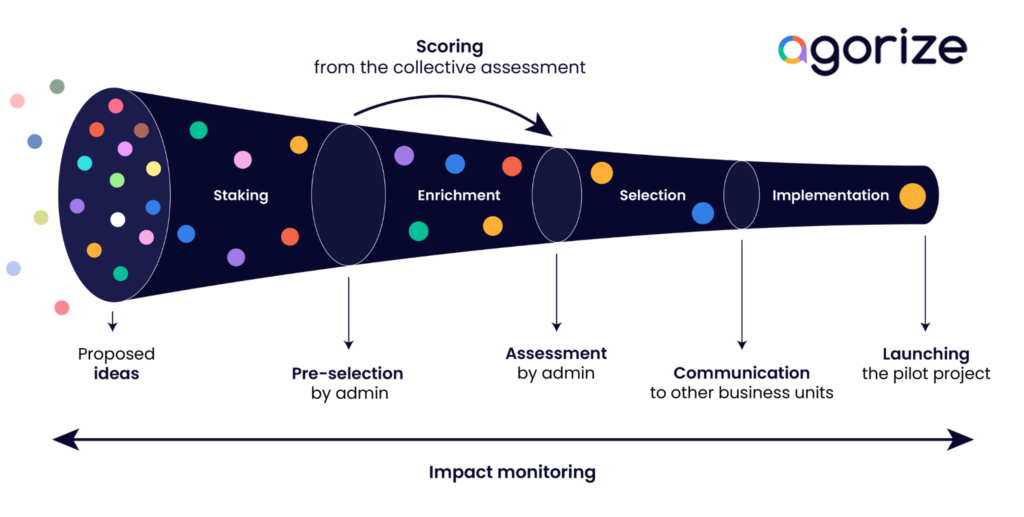

How does such a tool work? These are common steps to follow when using idea management software.

Plan: Every time you launch a call for ideas, you’ll start with a problem statement. This is where you focus on your most important objectives and translate it into a statement as well as categories for participants (employees or customers) to submit ideas in.

Build: Then, you build a platform with easy-to-use templates and enhance workflows so they meet your needs. Update settings to assign points to highly engaged people to keep them involved, or schedule your communication for the coming weeks and months.

Reveal: After launch, you’ll use the idea management software to collect improvement ideas.

Assess: Invite others to share their feedback, then drag-and-drop them to the next phase in your ideation funnel.

Implement: The next phase is testing different ideas and hypotheses. You’ll likely ask for input from subject matter experts and even C-level management to identify the next steps, like a PoC.

Conclusion

So, continuous improvement is pursued by companies whether their current survival depends on it or they simply want to go from good to great. And while the many improvement techniques have a foundational role in our understanding of this continuous improvement, today’s business landscape calls for solutions that can bridge the gap from framework to ROI, or idea to PoC.

Thus, use the 5 essentials of digital continuous improvement tools to start this journey and opt for a solution that remembers the human elements of collective intelligence.

However, if you are still not sure about what next steps to take, then our team of innovation experts is happy to share more best practices. Because of our insights based on 12+ years of experience with over 300 enterprise customers across the globe we can help craft a solutions that meets your needs. So, let’s accelerate your transformation end-to-end, together.

– Kanban: This is a visual method to illustrate, measure, and highlight focus areas to enable continuous improvement.

– Kaizen Continuous Improvement: Originally, it is a Japanese philosophy built around the importance of flexible and open processes and systems. It helps organizations improve by constantly identifying and addressing issues.

– Plan-Do-Check-Act (PDCA): This method is an adaptation of Kaizen. The original goal was to manage quality control and the reasoning behind the technique is straightforward. The PDCA cycle, consists of Plan, Do, Check, Act.

– Six Sigma: The Six Sigma techniques help limit errors to improve an organization’s capabilities. Six Sigma often uses PDCA for the implementation

Continuous improvement, often referred to as continuous improvement process (CIP) or continuous improvement management (CIM), is an ongoing effort within an organization to enhance products, services, or processes. The goal is to make incremental, consistent advancements over time to achieve higher efficiency, quality, and overall performance. Continuous improvement is a fundamental principle of various management philosophies, including Total Quality Management (TQM) and Lean methodologies. Continuous improvement is not a one-time initiative but rather a mindset and organizational culture that values ongoing learning, adaptation, and growth. It is essential for staying competitive in dynamic business environments.